Automation is at the core of modern industry, boosting productivity and streamlining operations across various sectors. However, the secret behind efficient automation lies in its engineering design. With precise planning, robust system integration, and innovative solutions, engineering design ensures that automation systems achieve optimal performance. If you’re seeking customized solutions for your industrial automated systems, understanding the role of engineering design is essential. Let’s explore how this process makes automation more efficient.

1. The Role of Engineering Design in Automation

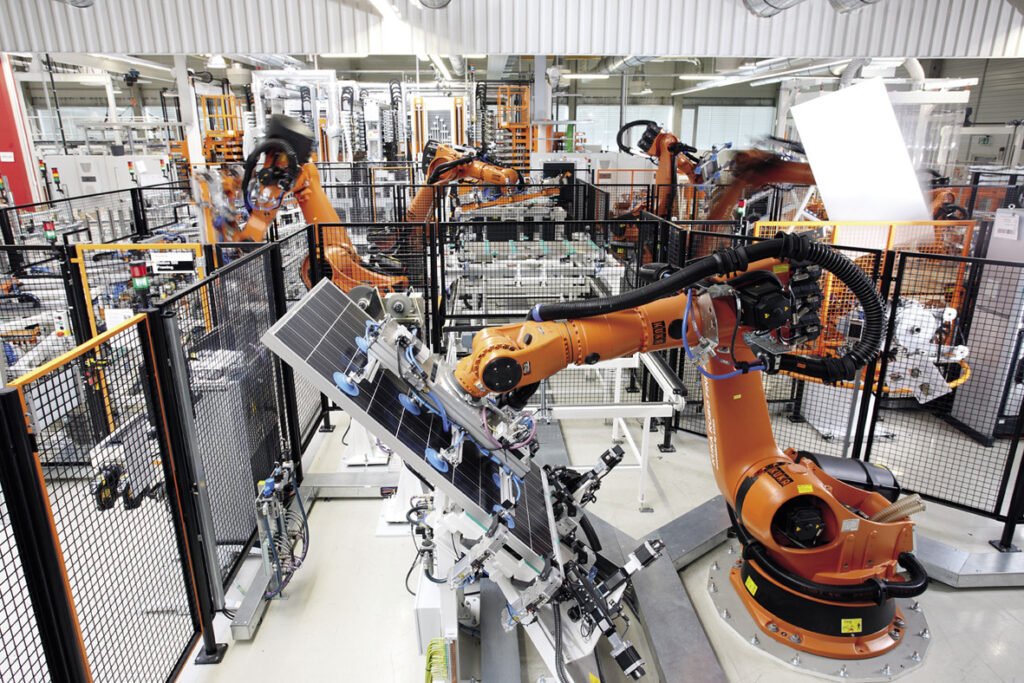

Bridging the Gap Between Concept and Reality

Engineering design transforms theoretical automation concepts into practical, functional systems. It involves detailed planning, choosing the right components, and integrating them seamlessly to meet specific operational goals.

Improving System Functionality

Good design ensures that automation systems are not only functional but also optimized for efficiency. This means reducing waste, improving accuracy, and ensuring reliable operation.

2. Identifying and Meeting System Requirements

Tailoring Systems to Industry Needs

Every industry has unique requirements. For instance, the needs of a manufacturing plant differ significantly from those of a logistics center. Engineers must customize designs to align with these specific demands.

Defining Clear Objectives

Engineering design begins with a clear understanding of what the system needs to achieve. This includes identifying key performance indicators (KPIs), operational constraints, and budget limitations.

3. Streamlining Component Integration

Ensuring Compatibility

Modern automation systems often involve a mix of hardware and software from different manufacturers. Engineering design focuses on ensuring these components work harmoniously.

Minimizing Integration Delays

A well-designed system minimizes the risk of delays caused by incompatible components or software glitches, enabling quicker deployment.

4. Enhancing System Scalability

Preparing for Future Growth

A key aspect of engineering design is planning for scalability. As businesses grow, their automation systems must adapt without requiring a complete overhaul.

Incorporating Modular Designs

Using modular components allows for easier upgrades and expansions, ensuring the system can evolve with the organization’s needs.

5. Improving Energy Efficiency

Optimizing Power Usage

Energy efficiency is a significant factor in automation design. Engineers strive to minimize energy consumption without compromising system performance.

Using Smart Technologies

Smart sensors, energy-efficient motors, and intelligent control systems are integrated to enhance overall efficiency and reduce operational costs.

6. Addressing Safety and Reliability

Ensuring Safe Operations

Safety is a priority in automation design. Engineers incorporate safety features such as emergency stop functions, fail-safes, and real-time monitoring to protect both operators and equipment.

Maximizing Uptime

Reliability is critical for automation systems. Engineering design focuses on reducing the likelihood of breakdowns by using high-quality components and robust configurations.

7. Leveraging Data for Continuous Improvement

Integrating IoT and Analytics

The Internet of Things (IoT) plays a significant role in modern automation. By collecting and analyzing data, engineers can identify inefficiencies and optimize system performance.

Real-Time Monitoring

Engineering design often includes tools for real-time monitoring, enabling businesses to detect and resolve issues promptly.

8. Reducing Costs Through Smart Design

Minimizing Initial Investment

A well-thought-out design can reduce upfront costs by selecting cost-effective yet reliable components and avoiding unnecessary complexities.

Lowering Operational Costs

Energy efficiency, reduced maintenance needs, and optimized processes all contribute to lower long-term costs.

9. Promoting Sustainability

Designing Eco-Friendly Systems

Sustainability is increasingly important. Engineers incorporate eco-friendly practices, such as using recyclable materials and reducing energy consumption, into automation designs.

Meeting Environmental Regulations

Automation systems must comply with environmental regulations, and engineering design ensures adherence while maintaining efficiency.

10. Incorporating Advanced Technologies

Artificial Intelligence and Machine Learning

AI and ML technologies are now integral to automation systems. Engineering design leverages these technologies to enable predictive maintenance, adaptive operations, and smarter decision-making.

Collaborative Robots (Cobots)

Cobots are designed to work alongside humans, enhancing productivity and safety. Their integration is a growing trend in automation design.

11. Overcoming Challenges in Automation Design

Addressing Technological Complexities

Engineers often face challenges such as integrating legacy systems or managing complex workflows. A solid engineering design process addresses these issues effectively.

Adapting to Industry-Specific Needs

Different industries require specialized solutions. For example, automation in healthcare focuses on precision and safety, while logistics emphasizes speed and efficiency.

12. Conclusion: Unlocking Efficiency Through Design

Engineering design is the backbone of efficient automation systems. From ensuring seamless integration to leveraging advanced technologies, it plays a vital role in optimizing performance, reducing costs, and preparing for the future.